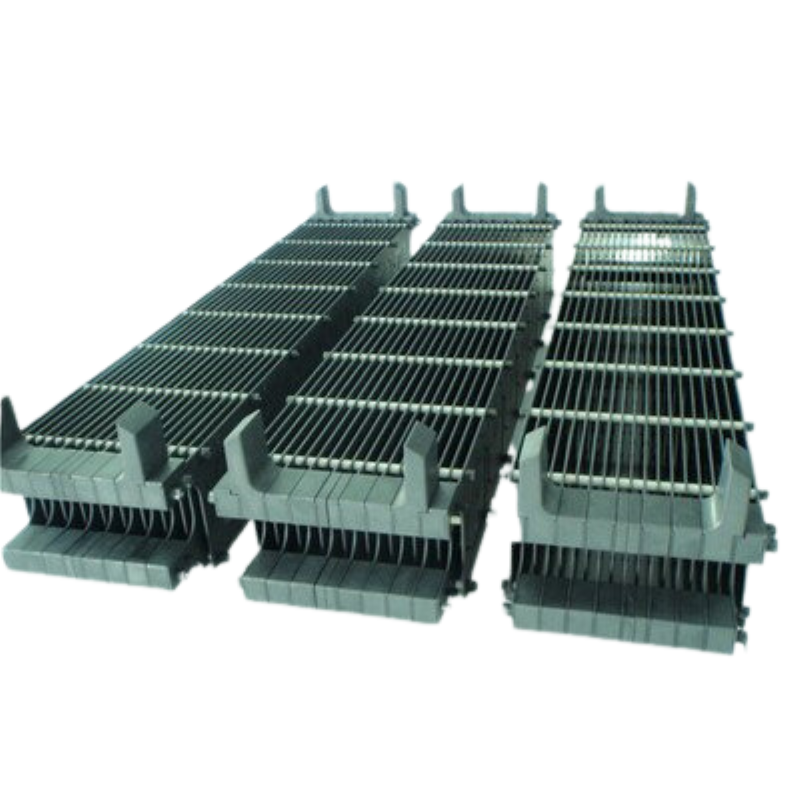

EDM Graphite Mold: Precision in Electrical Discharge Machining

Brief Description: Elevate your machining precision with our EDM Graphite Mold. Engineered for electrical discharge machining, it ensures superior accuracy, durability, and efficiency in intricate mold production.

Application: Ideal for tool and die makers, our graphite mold excels in precision molding for industries like aerospace, automotive, and electronics.

Type and Technical Data:

| Type | Technical Data |

|---|---|

| EDM Graphite Mold | Material: High-density graphite alloy |

| Machining Precision: [Specify precision level] | |

| Application: Electrical discharge machining | |

| Longevity: Extended mold life |

How to Use EDM Graphite Mold:

1.Preparation:

Inspect the graphite mold for any contaminants or irregularities.

Ensure the EDM machine is calibrated for the desired precision level.

2.Material Placement:

Securely place the workpiece material into the graphite mold.

Ensure proper alignment for precision molding.

3.EDM Machining:

Initiate the electrical discharge machining process with carefully adjusted parameters.

Monitor the machining progress to ensure accurate and efficient mold production.

4.Cleaning and Inspection:

After machining, carefully remove the molded workpiece from the graphite mold.

Inspect the mold for any wear or irregularities, and clean if necessary.

5.Maintenance:

Regularly clean the graphite mold to remove any residual material.

Store the mold in a cool, dry place to prolong its longevity.

Enhance your mold production with our EDM Graphite Mold—where precision meets efficiency for superior electrical discharge machining results.