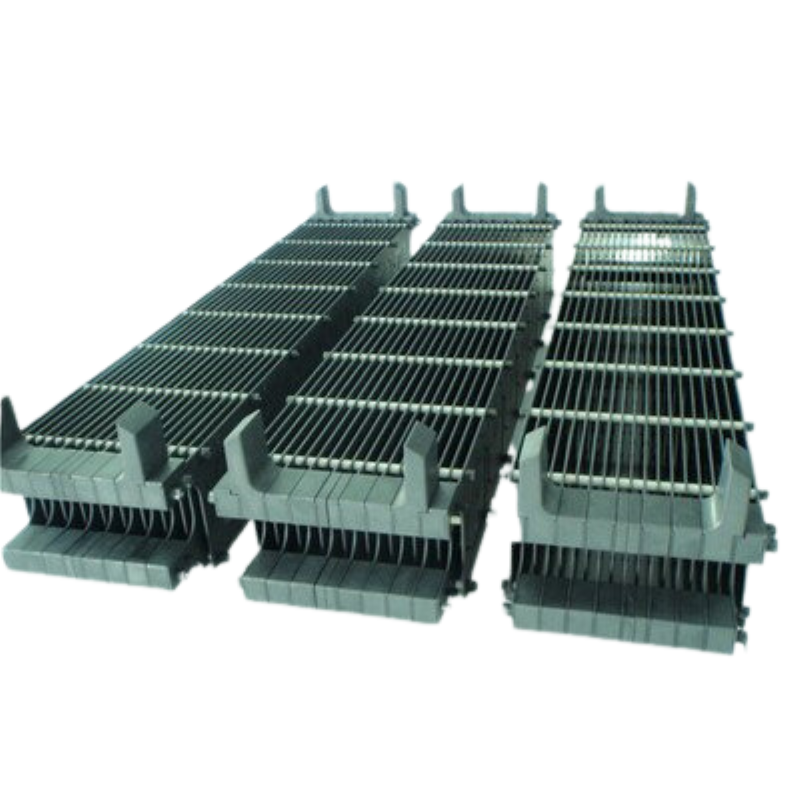

Brief Description: Elevate your copper tubing production with our state-of-the-art Graphite Molds. Crafted with precision and engineered excellence, our molds redefine manufacturing standards. We seamlessly blend cutting-edge technology with a commitment to quality, ensuring your copper tubing achieves unparalleled precision and consistency.

Application: Our Graphite Molds for Copper Tubing find their niche in a spectrum of industries, including electrical, plumbing, and HVAC. Perfect for creating intricate designs and precise dimensions, these molds guarantee a flawless finish, minimizing waste and maximizing productivity.

Type and Technical Data (Table):

| Graphite Mold Type | Technical Specifications |

|---|---|

| Precision Mold | High thermal conductivity for uniform heat distribution |

| Customizable Shapes | Tailored to meet specific design and dimension needs |

| Durability | Long lifespan, resistant to wear and thermal stress |

| Heat Resistance | Withstands extreme temperatures for consistent results |

| Surface Finish | Smooth finish for superior copper tubing aesthetics |

| Dimensional Accuracy | Maintains tight tolerances for precise tubing production |

Our Graphite Molds for Copper Tubing empower your production process with precision, reliability, and efficiency. Crafted for diverse applications, these molds ensure optimal results in electrical, plumbing, and HVAC industries. The technical prowess of our molds guarantees high thermal conductivity, customizable shapes, exceptional durability, heat resistance, impeccable surface finish, and dimensional accuracy. Elevate your copper tubing manufacturing with our cutting-edge solutions.

How to Use Graphite Molds for Copper Tubing: A Professional Engineer’s Guide

1.Preparation: Ensure the graphite mold is clean and free from any contaminants. Properly inspect the mold for any signs of damage or wear.

2.Material Selection: Choose high-quality copper material that meets the specifications of your design. Ensure the material is clean and free from impurities.

3.Preheating: Preheat the graphite mold to the recommended temperature to ensure uniform heat distribution during the molding process. This step is crucial for achieving consistent results.

4.Molding Process: Carefully place the preheated mold into the molding machine. Feed the copper material into the mold, making sure it fills all the cavities evenly. Apply pressure according to the material specifications.

5.Cooling: Allow the molded copper tubing to cool gradually within the mold. Avoid sudden temperature changes to prevent thermal stress and ensure the desired dimensional accuracy.

6.Extraction: Gently extract the cooled copper tubing from the mold. Inspect the final product for any imperfections and make adjustments to the process if necessary.

7.Cleaning and Maintenance: After use, clean the graphite mold thoroughly to remove any residue. Store the mold in a cool, dry place to extend its lifespan.

By following these steps, you’ll harness the full potential of our Graphite Molds for Copper Tubing, ensuring precision, efficiency, and top-notch quality in your manufacturing process.