A graphite resistance heater is a widely used heating element in high-temperature processing equipment, particularly in vacuum furnaces, high-temperature ovens, and other heat treatment devices. Here is some important information about graphite resistance heaters:

1.Working Principle:

The working principle of a graphite resistance heater is based on the resistive heating effect. When an electric current passes through the graphite resistance heater, the electrical resistance of the graphite material generates heat. This heat causes the graphite heater to increase in temperature, subsequently transferring heat to the surrounding environment or objects.

2.Advantages and Characteristics:

High-Temperature Stability: Graphite exhibits excellent stability at high temperatures, maintaining the structural stability and mechanical properties under extreme temperature conditions.

Conductivity and Thermal Conductivity: Graphite possesses good electrical conductivity and thermal conductivity, allowing it to efficiently generate and transfer heat when an electric current passes through, achieving uniform heating.

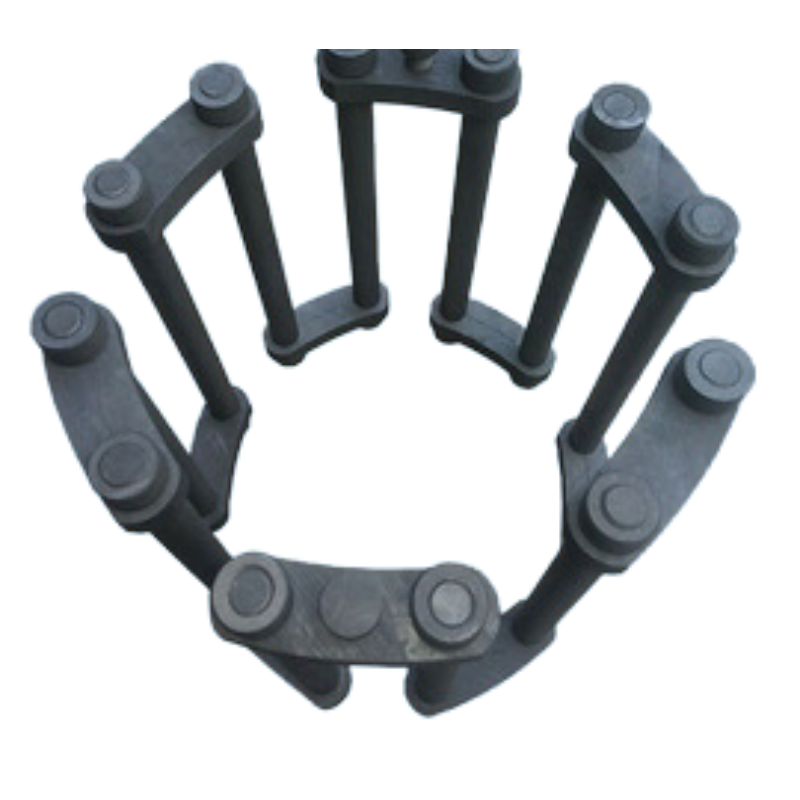

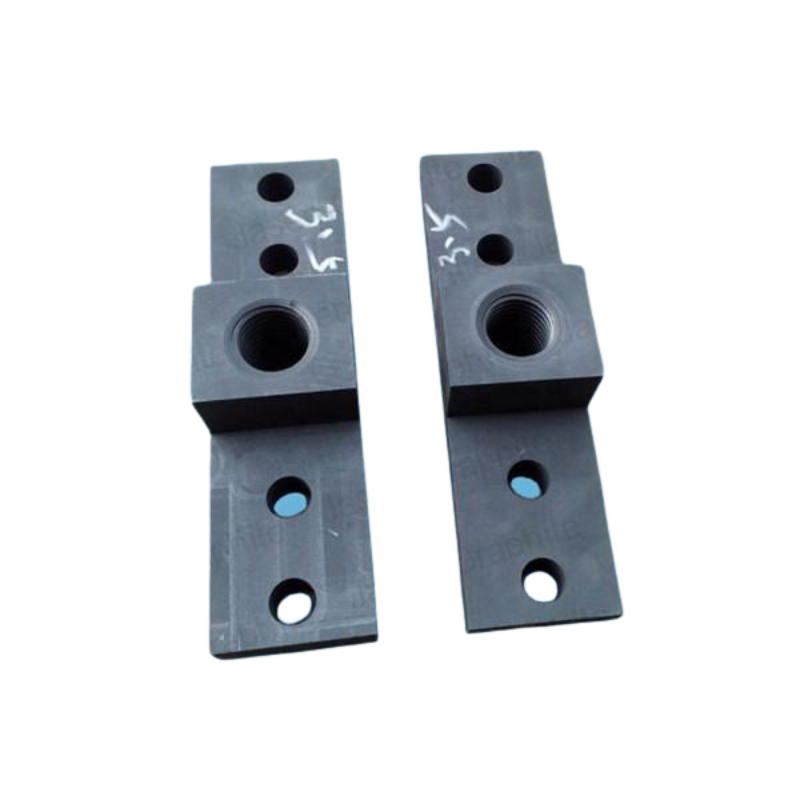

Customizability: Graphite resistance heaters can be designed and manufactured according to specific application requirements, including customization of shape, size, and resistance characteristics.

Rapid Responsiveness: Due to its thermal conductivity, graphite resistance heaters typically feature fast response times, enabling quick heating and cooling.

3.Application Areas:

Vacuum and High-Temperature Furnaces: Graphite resistance heaters are widely used in vacuum and high-temperature furnaces for various heat treatment processes such as annealing, quenching, tempering, and more.

Material Sintering: In ceramic and powder metallurgy processes, graphite resistance heaters are extensively employed in sintering applications.

Laboratory Research: Owing to its high-temperature stability and customizable properties, graphite resistance heaters are frequently utilized in laboratory experiments and material research.

4.Precautions and Maintenance:

Preventing Atmosphere Leaks: When operating in vacuum or special atmospheres, ensuring the sealing performance of graphite resistance heaters is essential to prevent atmosphere leaks that may impact the process.

Protective Measures: Adequate protective measures should be taken during high-temperature operations to safeguard operators and equipment.

Regular Inspection and Maintenance: Regularly inspecting the status of graphite resistance heaters and performing necessary maintenance and cleaning are crucial to ensure their performance and longevity.

In summary, graphite resistance heaters play a crucial role in high-temperature processing, providing a reliable and effective heating solution for industrial production and laboratory research.