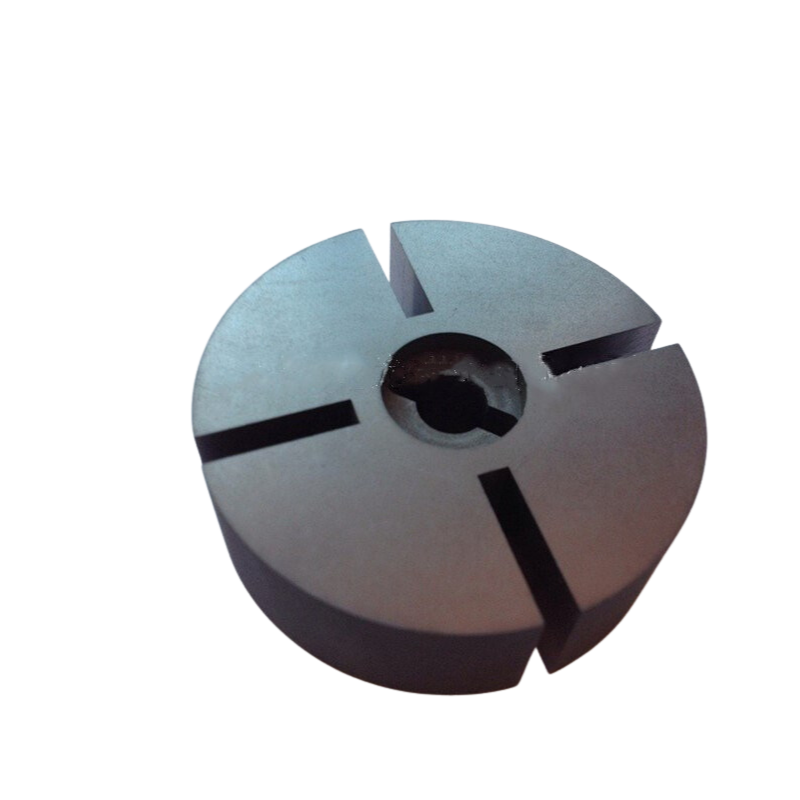

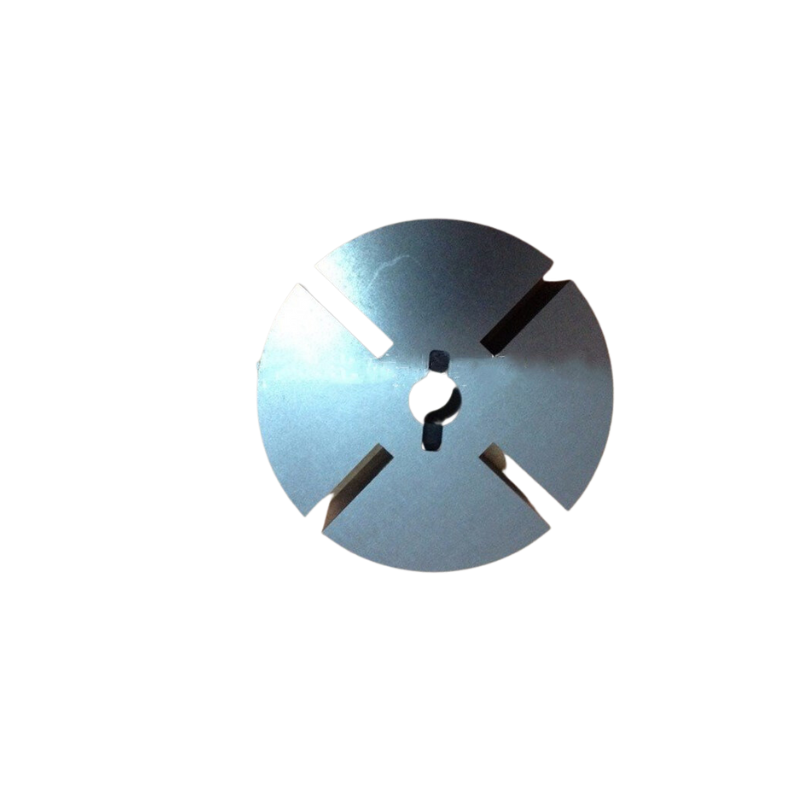

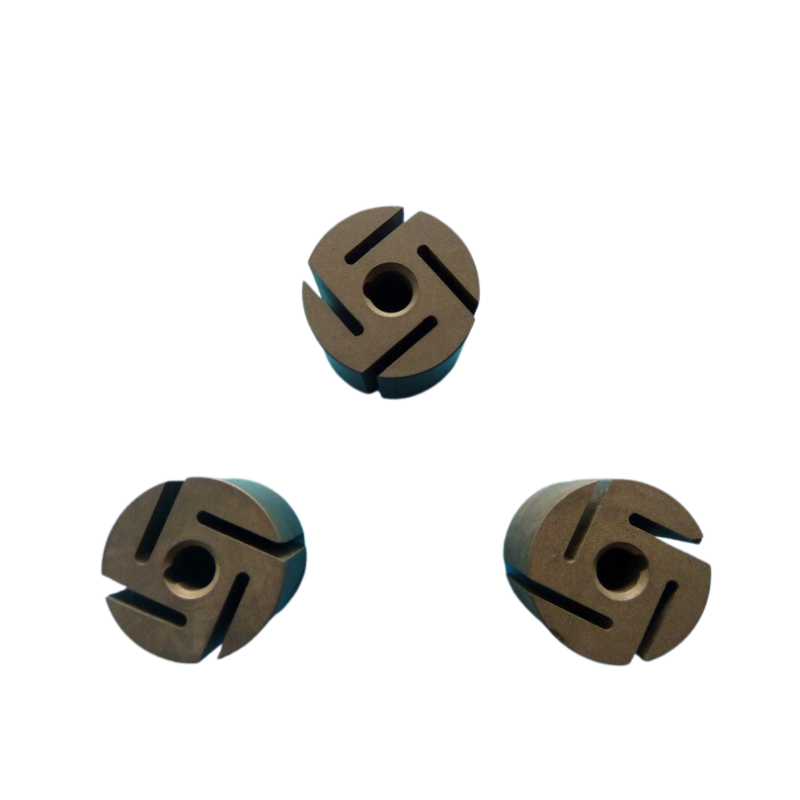

Brief Description: Discover peak efficiency with our Graphite Rotor, a pinnacle of precision engineering. This high-quality component ensures optimal performance and durability, revolutionizing industrial processes.

Application: Ideal for a spectrum of industries, our Graphite Rotor excels in applications demanding reliability and precision. From manufacturing to energy production, it enhances performance across diverse sectors.

Type and Technical Data:

| Type | Technical Data |

|---|---|

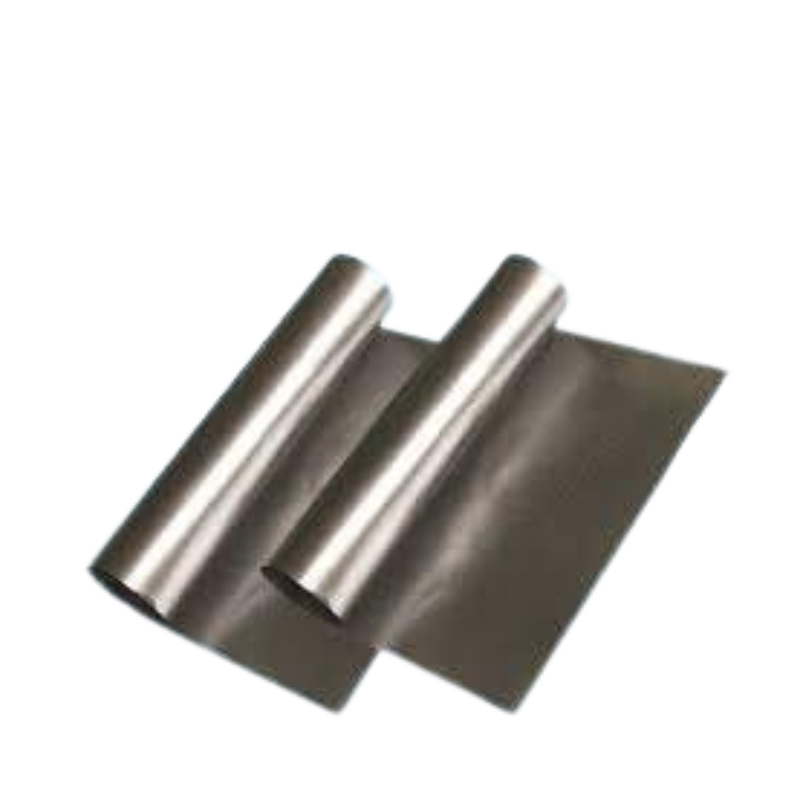

| Graphite Rotor | High-density graphite composite |

| Dimensions | Customizable per application |

| Operating Temp | -50°C to 500°C |

| Max RPM | Achieves up to 10,000 RPM |

| Tolerance | ±0.005mm for precise operations |

How to Use “Graphite Rotor” – Professional Engineer’s Guide:

1.Installation: Ensure a clean, debris-free environment. Align the Graphite Rotor meticulously with your machinery specifications. Tighten securely to prevent misalignment.

2.Operational Parameters: Check compatibility with operating temperatures and RPM requirements. Adjust as needed to optimize performance and longevity.

3.Maintenance: Periodically inspect for wear and tear. Replace when necessary, following manufacturer guidelines. Keep the Graphite Rotor clean to prevent performance degradation.

4.Customization: Tailor the Graphite Rotor dimensions to your specific application. Consult with our technical team for personalized solutions.

5.Performance Monitoring: Regularly monitor performance metrics, such as RPM and temperature. Implement preventive measures based on data analysis for enhanced efficiency.

Elevate your operations with the Graphite Rotor, a testament to innovation and reliability. Unleash the power of precision in every rotation.