Brief Description:

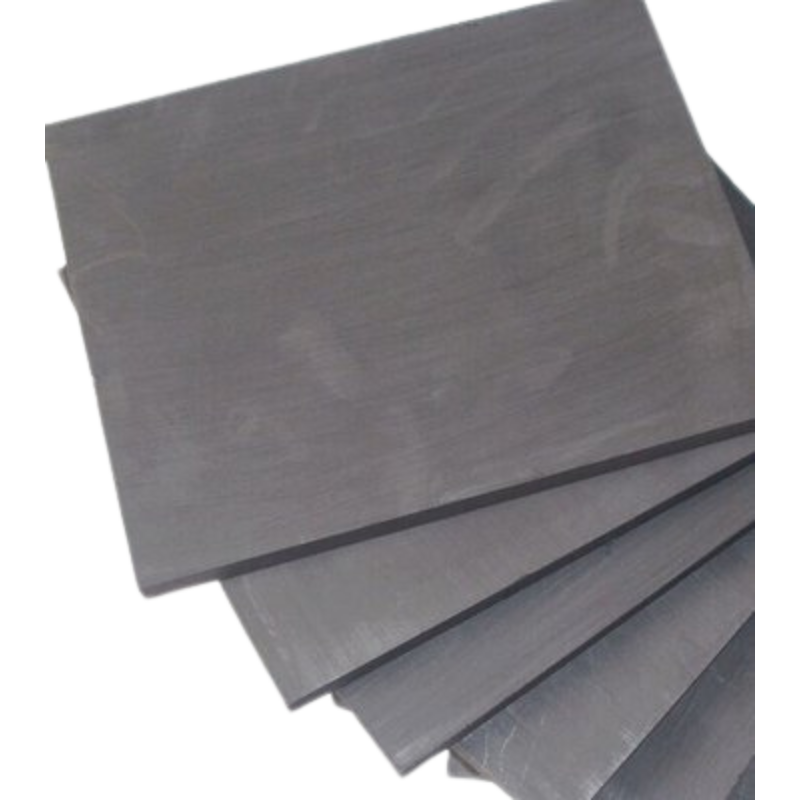

Elevate your projects with our High-Purity Graphite Board, a pinnacle of excellence in material engineering. Crafted to surpass purity standards, this graphite board seamlessly integrates durability, versatility, and high performance, setting a new benchmark in precision applications.

Applications:

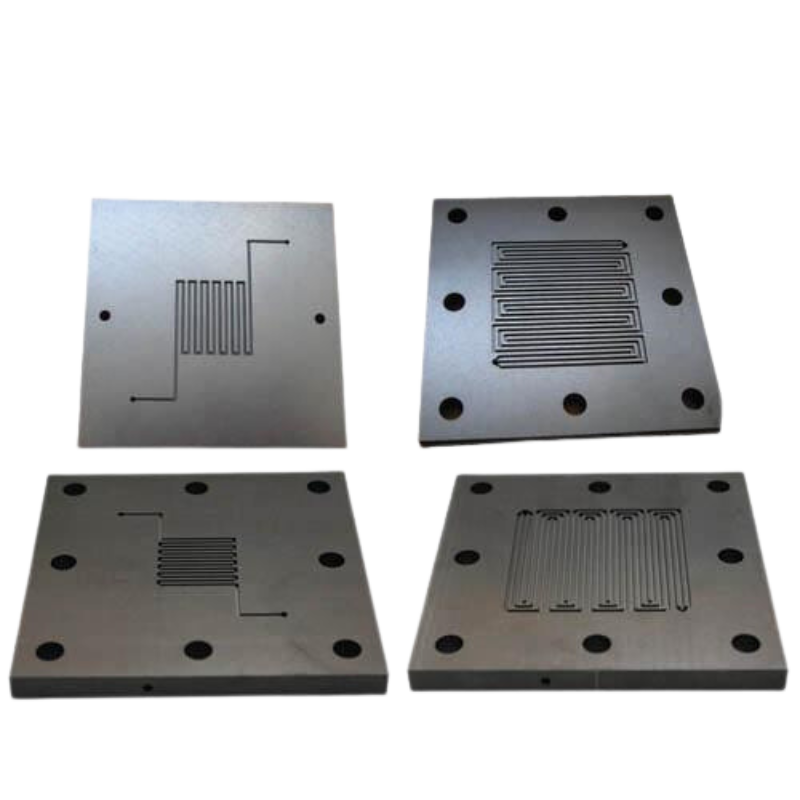

Unleash the potential of High-Purity Graphite Board across industries:

1.Semiconductor Manufacturing: Delivers unmatched precision and reliability in high-temperature furnaces.

2.Energy Storage Systems: Optimizes thermal management for enhanced efficiency and safety in batteries.

3.Aerospace Technologies: Provides lightweight yet robust solutions for extreme environmental conditions.

4.Electronics: Ensures superior heat dissipation, extending the lifespan of electronic components.5.Foundry and Metallurgy: Facilitates precise casting processes, ensuring consistency in metal production.

Type and Technical Data (Table):

| Property | High-Purity Graphite Board |

|---|---|

| Density | Ultra-Low |

| Thermal Conductivity | Exceptional |

| Flexural Strength | High |

| Electrical Resistivity | Superior |

| Purity Level | 99.9% |

| Operating Temperature | Up to 3000°C |

Seamlessly combining ultra-low density with exceptional thermal conductivity, our High-Purity Graphite Board offers unparalleled flexibility and strength. With a purity level of 99.9%, it thrives in operating temperatures up to 3000°C, making it the go-to solution for precision-critical applications.

How to Use High-Purity Graphite Board: A Professional Engineer’s Guide

As a professional engineer, the seamless integration of High-Purity Graphite Board into your projects involves the following steps:

1.Surface Preparation: Ensure the application surface is clean and free of contaminants for a secure and efficient bond.

2.Cutting and Shaping: Utilize standard cutting tools to easily shape the versatile High-Purity Graphite Board according to project specifications.

3.Installation: Secure the graphite board using appropriate adhesives or fastening methods, ensuring a snug fit to maximize thermal and structural benefits.

4.Temperature Considerations: Given its exceptional thermal stability, employ High-Purity Graphite Board in applications within the recommended temperature range for optimal performance.

5.Maintenance: Periodically inspect the board for wear or damage, replacing as needed to uphold the integrity of your application.

Integrate excellence effortlessly into your projects with High-Purity Graphite Board – where precision meets performance, and innovation finds its foundation.