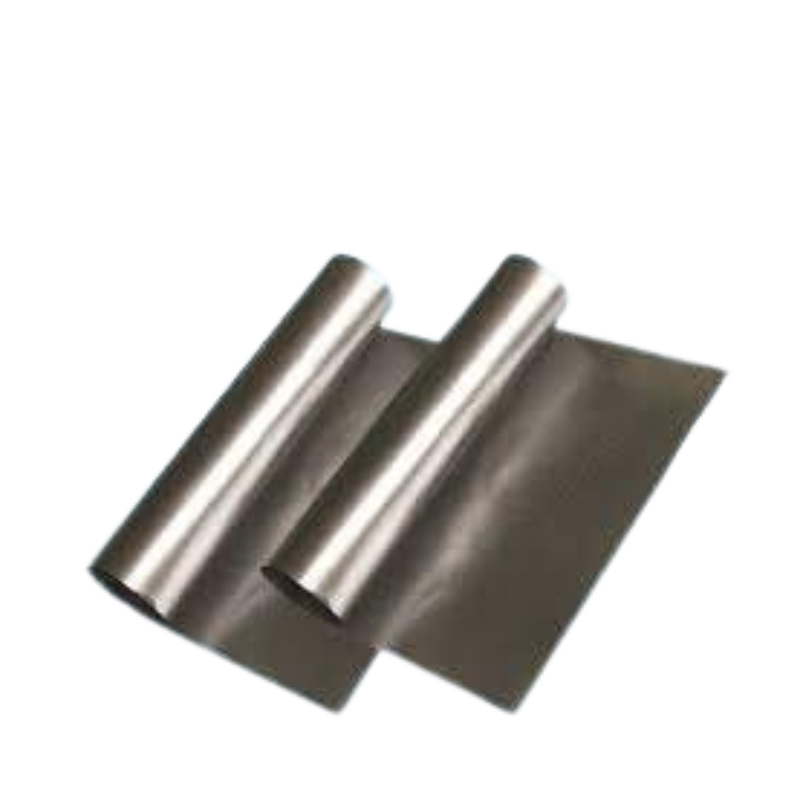

Brief Description: Discover unparalleled conductivity and durability with our cutting-edge solution – “Impregnated Graphite.” A marvel in material science, this graphite-infused product is engineered for excellence, elevating your projects to new heights.

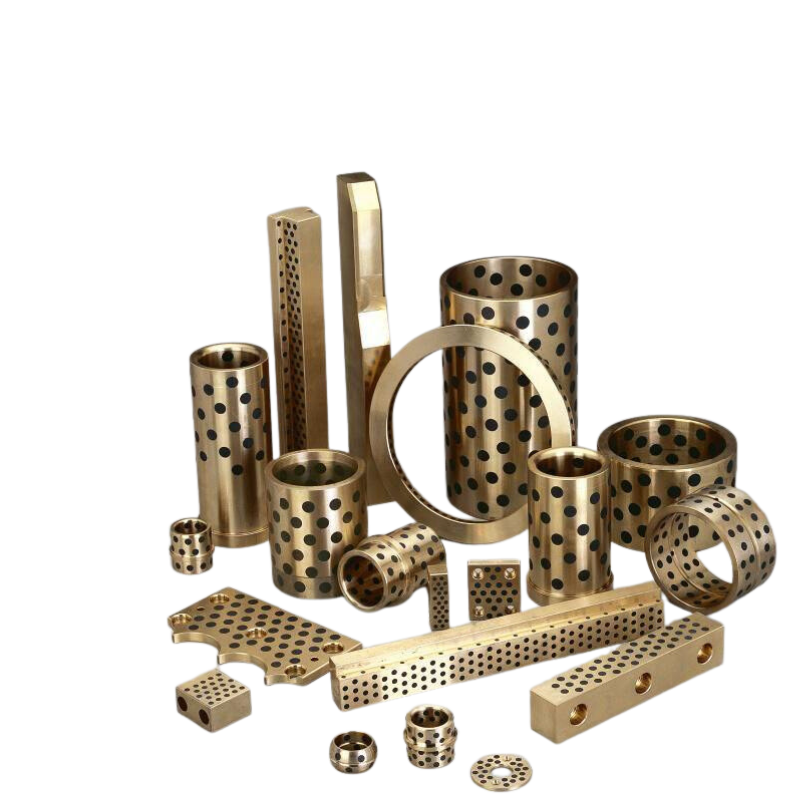

Application: Unlock the potential across diverse industries. From high-performance electronics to robust industrial machinery, our Impregnated Graphite ensures optimal efficiency, reliability, and longevity.

Type and Technical Data:

| Property | Specification |

|---|---|

| Material Type | High-Quality Graphite |

| Impregnation Technique | Advanced Infusion Process |

| Conductivity | Superior Electrical Performance |

| Durability | Exceptional Wear Resistance |

| Temperature Range | Wide Operating Temperature Range |

| Applications | Electronics, Machinery, and more |

How to Use “Impregnated Graphite” – Professional Insights:

As a seasoned engineer, optimizing the benefits of “Impregnated Graphite” requires strategic implementation:

1.Identify Application: Determine the specific requirements of your project, considering conductivity, wear resistance, and operating conditions.

2.Surface Preparation: Ensure the application surface is clean and free from contaminants, promoting optimal adhesion during the infusion process.

3.Precision Infusion: Employ precise techniques during the impregnation process to achieve uniform distribution of the graphite, enhancing conductivity and durability.

4.Compatibility Check: Verify compatibility with other materials in your system to avoid potential reactions and ensure seamless integration.

5.Quality Assurance: Regularly assess the performance of “Impregnated Graphite” to maintain peak efficiency, especially in high-demand applications.

Incorporate these steps into your engineering practices, and witness the transformative impact of “Impregnated Graphite” on your projects. Elevate performance, enhance reliability, and embrace the future of material innovation.