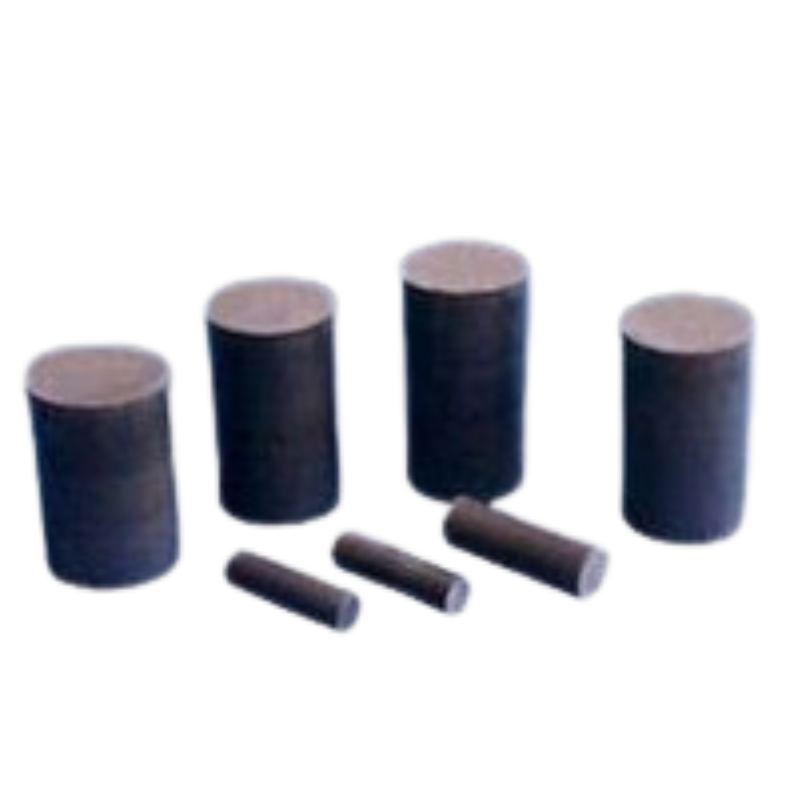

Isostatic Graphite: Precision Redefined for High-Temperature Excellence

Brief Description: Elevate your industrial processes with our Isostatic Graphite – a pinnacle of precision and durability. Engineered for high-temperature applications, it sets the standard for excellence.

Applications: Ideal for:

- Semiconductor manufacturing

- Solar cell production

- Aerospace applications

- EDM (Electrical Discharge Machining)

- Crucibles for metal casting

Type and Technical Data :

| Feature | Specification |

|---|---|

| Material Type | High-density Isostatic Graphite |

| Thermal Conductivity | Exceptional heat transfer capabilities |

| Density | Uniform and high-density structure |

| Particle Size | Fine-grain structure for precision |

| Oxidation Resistance | Superior resistance to high temperatures |

| Applications | Versatile for various industrial uses |

How to Use Isostatic Graphite: A Professional Engineer’s Guide:

1.Surface Preparation: Ensure the work surface is clean and free from debris. Place the Isostatic Graphite block securely.

2.Cutting and Shaping: Use precision tools to cut or shape the Isostatic Graphite according to your specific requirements. Ensure proper safety measures.

3.Machining: Employ CNC machining for intricate designs. Isostatic Graphite’s fine-grain structure allows for precise machining with minimal tool wear.

4.Heat Applications: Isostatic Graphite excels in high-temperature environments. Use it for crucibles, molds, or fixtures in processes like metal casting or semiconductor manufacturing.

5.EDM Electrodes: For EDM applications, create custom electrodes from Isostatic Graphite. Its exceptional conductivity ensures efficient material removal.

6.Cleaning and Maintenance: After use, clean the Isostatic Graphite using appropriate methods. Inspect for any wear or damage, ensuring longevity and consistent performance.

Leverage the power of Isostatic Graphite for unparalleled precision and longevity in your high-temperature industrial applications. Redefine excellence today!