Knowledge

-

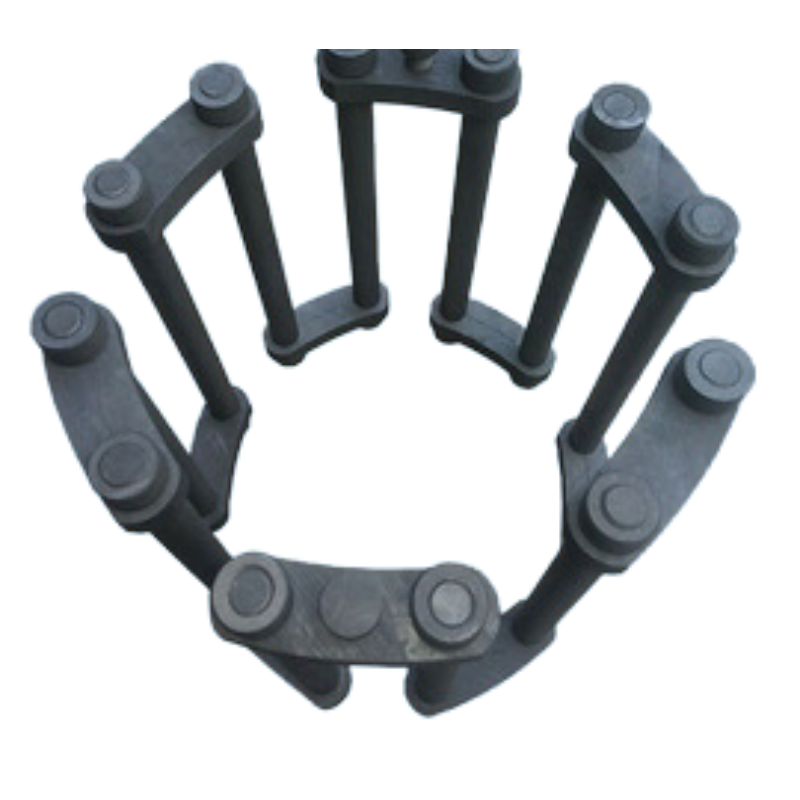

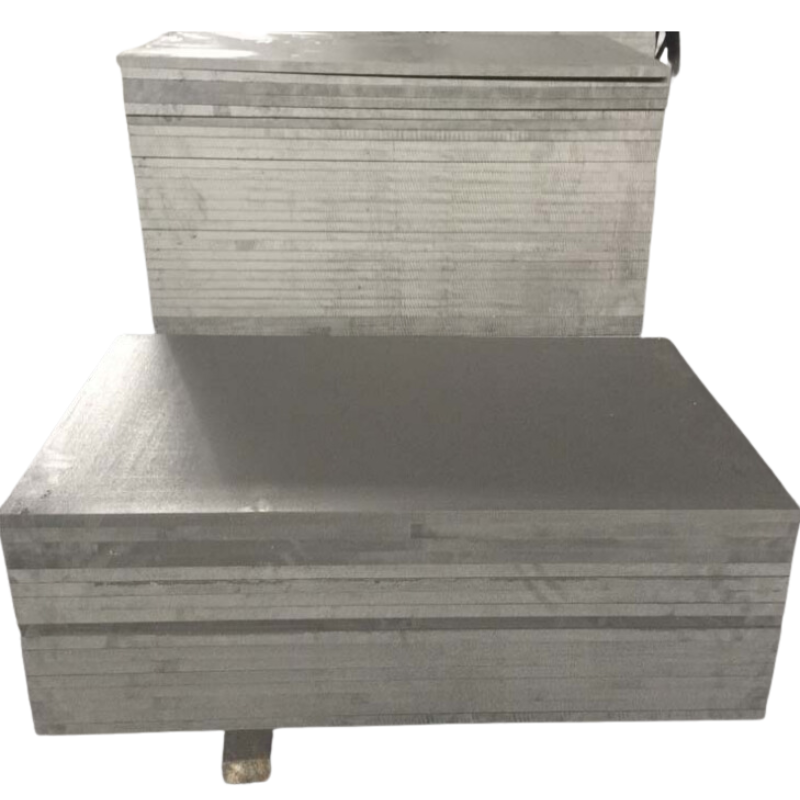

Common types of graphite mold parts

Molds are widely used fundamental industrial equipment, and the mold industry is a cornerstone of the national economy. In modern industrial production, product parts are extensively produced using...

-

What is EDM Graphite?

EDM graphite, or Electrical Discharge Machining Graphite, is a specialized graphite material used for electrical discharge machining (EDM). EDM is a precision machining method that remove...

-

Scaling factors and cleaning methods of graphite heat exchangers

Causes of Fouling 1.Fluid Flow Velocity: The velocity of the fluid affects fouling through its impact on heat and mass transfer and mechanical forces, making the process quite complex. In fact,...

-

Benefits of adding graphite powder during steel smelting

Adding graphite powder during steel smelting offers several benefits, including the following: 1.Increasing Carbon Content: Graphite powder is a pure carbon material that can increase the car...

-

Method for improving the density of graphite products

1.Increasing the volume shrinkage to increase the bulk density of the deposit. After graphitization, the weight loss of the calcined product is about 2.6%. If you want to increase the bulk densi...

-

Method for improving the density of graphite products

1. Increasing Volume Contraction to Enhance Bulk Density The weight loss of calcined products during graphitization is about 2.6%. To increase the bulk density of bio-products in the graphitizatio...